·

What is our requirement?

ð Here we want to measure the rpm of DC motor.

So we have to measure how many times a particular point on the rotor undergoes

a full rotation within a minute. So we have to use a sensor to keep track of

this data.

If we are able to determine the time between

two consecutive detection of fixed point then we can calculate the RPM easily.

Suppose the time between two consecutive detection is ‘t millisecond(s)’ then

In our

project we have used infrared sensor (IR sensor) for detection of fixed point.

This is all

about the basic requirement. Now we will see the basic block diagram of the

circuit we are going to make.

·

Block diagram of the circuit.

Now let us

see those units in our project, just overview.

Motor: -

Sensor: -

Processing unit: -

Power: -

Display: -

·

What components are required?

·

The required components

are –

a. 470 ohm [470 Ω 1/4W], 1/4 Watt Resistor

b. 10K ohm [10K Ω 1/2W], 1/2 Watt Resistor

c. 16Mhz Crystal

d. 9v Battery Zinc Chloride Battery

e. 9v Battery Snap Connector

f.

22pf/50V Ceramic

Capacitor

g. CD4511 - BCD to 7-segment Latch/Decoder/Driver

h. 28 Pin - DIP IC Socket/Base (DIP-28pin)

i.

3mm IR

Transmitter & Reciever [Rx - Equ. Phototransistor]

j.

Touch Switch -

Push button (4pin Tactile-Micro) Switch – small

k. PCB Board Universal - Perforated [Tin Plated]

2x3" inches

l.

Knob

Potentiometer - Small (inner semi-circle)

m. 10K Potentiometer (Linear)

n. Atmega8A-8PU Microcontroller

o. Wheels for BO motors - Dia 6.8cm (68mm) |

0.8cm(8mm) width - D shape hole

p. 300 RPM Straight DC Geared BO motor Single Shaft

q. 16 Pin - DIP IC Socket/Base (DIP-16pin)

r. 7-Segment Display - Common Cathode

s. 40x2 pin break-away Headers- Straight male

Headers

t.

40 pin Female

Berg strip - Straight Female Headers

That’s all. They are bought from – http://www.electronicscomponents.com/

·

What is the processing unit?

·

Here the

processing unit refers to the unit that is the heart of that measurement

device. It is responsible for the control of sensors, display. It does all the

mathematic operation required to calculate the rpm.

Here we have used Atmega8A-PU

microcontroller which is popularly known to be used in Arduino board.

·

Reasons for using microcontroller instead of

using discrete chips.

·

Since the

capability of a single microcontroller is beyond the discrete chips. Reasons

can be summarised as follows –

a. It will be cost effective w.r.t the individual

components. For example Atmega8A-PU is available at INR 99 only.

b. It is programmable; we change the programme

anytime, vary the sensitivity and store the results.

c. Circuit

will be small and compact, error detection will be easy.

d. High speed of operation.

DESCRIPTION OF THE INDIVIDUAL COMPONENTS

·

Atmega8A-PU microcontroller: -

·

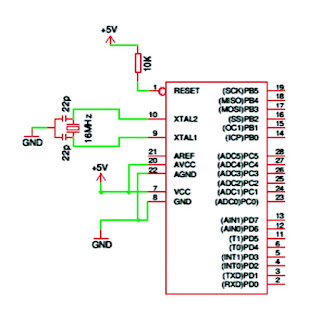

The pin-out of

that microcontroller is –

Atmega8A - 28Pins 8MHz 8kb 8-bit Microcontroller

Feature

- 28-pin AVR Microcontroller

- Flash Program Memory: 8 kbytes

- EEPROM Data Memory: 512 bytes

- SRAM Data Memory: 1 kbytes

- I/O Pins: 23

- Timers: Two 8-bit / One 16-bit

- A/D Converter: 10-bit Six Channel

- PWM: Three Channels

- RTC: Yes with Separate Oscillator

- MSSP: SPI and I²C Master and Slave Support

- USART: Yes

- External Oscillator: up to 8MHz

Specifications

- High-performance, Low-power AVR 8-bit

Microcontroller

- Advanced RISC Architecture

- 130 Powerful Instructions - Most Single Clock

Cycle Execution

- 32 x 8 General Purpose Working Registers

- Up to 16 MIPS Throughput at 16MHz

- Fully Static Operation

- On-chip 2-cycle Multiplier

- Nonvolatile Program and Data Memories

- 8k Bytes of In-System Self-Programmable Flash

- Optional Boot Code Section with Independent

Lock Bits

- 512K Bytes EEPROM

- Programming Lock for Software Security

- 1K Byte Internal SRAM

- Peripheral Features

- On-chip Analog Comparator

- Programmable Watchdog Timer with Seperate

On-chip Oscillator

- Master/Slave SPI Serial Interface

- Two 8-bit Timer/Counters with Separate

Prescalar, Compare

- One 16-bit TImer/Counter with Seperate

Prescaler, Compare and Capture mode

- Real TIme Counter with Seperate Oscillator

- Four PWM Channels

- 8-channel, 10-bit ADC

- Byte-oriented Two-wire Serial Interface

- Programmable Serial USART

- Special Mircocontroller Features

- Power-on Reset and Programmable Brown-out

Detection

- Internal Calibrated RC Oscillator

- External and Internal Interrupt Sources

- Five Sleep Modes: Idle, ADC Noise Reduction,

Power-save, Power-down, Standby, and Extended Standby

- I/O and Packages

- 23 Programmable I/O Lines

- 28-pin PDIP, 32-lead TQFP, and 32-pad MLF

- Operating Voltages

- 4.5-5.5V for ATmega8L

- Speed Grades

- 0-16 MHz for ATmega8

- Power Consumption @ 4 MHz, 3V, and 35°C for

ATmega8L

- Active: 3.6mA

- Idle Mode: 10mA

- Power-down Mode: 0.5µA

Here

are using the digital pins only i.e. the pins 13, 12, 11, ….. up to 3.

We

are also using Arduino standalone circuit. For more details about Arduino

standalone circuit please visit -- https://www.arduino.cc/en/Main/Standalone

The

circuit diagram is as –

·

IR Sensor: -

·

We have used 3mm

IR transmitter and phototransistor as Rx.

IR Transmitter & Receiver - 3mm

General Description

This 3mm Transmitter & Receiver pair can be

used for various applications like used in remote controls, distance sensor,

object sensors, line sensors etc. The receiver(black color) can be used as

phototransistor.

Specifications:

- Working wavelength: 925-955nm.

- Size: 3mm

Blue

one is the Tx and the clack one is the Rx.

The

corresponding circuit i—

We are

monitoring the current in photodiode through Atmega PIN ~5.

·

Display:

-

·

Here we

have used common cathode 7-segment display as display. Corresponding circuit.

About

the CD4511 IC—

CD4511 - BCD to 7-segment Latch/Decoder/Driver

Category

|

Integrated Circuits (ICs)

|

Name

|

CD4511, BCD to 7-segment

Latch/Decoder/Driver

|

Family

|

CMOS

|

Series

|

4000

|

Mounting

Type

|

Surface Mount

|

No.

of Pins

|

16 (DIP)

|

Feature

- Contains a 4-bit Storage Latch, BCD-to-Seven

Segment Decoder and Output Drive

- Suitable for LED, Incandescent, Fluorescent or

LCD Readouts

- Blanking Input

- Lamp Test Provision

- Low Power TTL

The

corresponding circuit of our project is --

·

Circuit Diagram of our circuit: -

·

Atmega8A-PU Chip code :-

ð The corresponding code –

#include

<StopWatch.h>

StopWatch Sw;

int sensorpin=5,

count = 0,rpm=0, Elapsed=0 ;

void Display(int

value)

{

int e=0,f=0,g=0, a=0, b=0,c=0,d=0;

e=value/100;

/* Separating the first digit */

// Serial.println(e);

f=(value/10)-(e*10); /* Separating the second

digit */

// Serial.println(f);

g=value-((100*e)+(10*f)); /* Separating the last digit */

// Serial.println(g);

/*Decimal to Binary Conversion */

a=e%2;

b=e/2;

c=b/2;

b=b%2;

d=c/2;

c=c%2;

delay(100);

digitalWrite(8,LOW); /* Configuring the Latch enable pins */

digitalWrite(7,HIGH);

digitalWrite(6,HIGH);

LED(a,b,c,d);

delay(100);

a=f%2;

b=f/2;

c=b/2;

b=b%2;

d=c/2;

c=c%2;

delay(100);

digitalWrite(8,HIGH); /* Configuring the Latch enable pins */

digitalWrite(7,LOW);

digitalWrite(6,HIGH);

delay(100);

LED(a,b,c,d);

a=g%2;

b=g/2;

c=b/2;

b=b%2;

d=c/2;

c=c%2;

delay(100);

digitalWrite(8,HIGH); /* Configuring the Latch enable pins */

digitalWrite(7,HIGH);

digitalWrite(6,LOW);

delay(100);

LED(a,b,c,d);

digitalWrite(6,HIGH);

delay(100);

}

void LED(int a,

int b, int c, int d)

{

if(a==1)

{

digitalWrite(9,HIGH);

}

else

{

digitalWrite(9,LOW);

}

if(b==1)

{

digitalWrite(10,HIGH);

}

else

{

digitalWrite(10,LOW);

}

if(c==1)

{

digitalWrite(11,HIGH);

}

else

{

digitalWrite(11,LOW);

}

if(d==1)

{

digitalWrite(12,HIGH);

}

else

{

digitalWrite(12,LOW);

}

}

void setup() {

pinMode(5,INPUT);

pinMode(13,OUTPUT);

pinMode(8,OUTPUT);

pinMode(7,OUTPUT);

pinMode(6,OUTPUT);

pinMode(12,OUTPUT);

pinMode(11,OUTPUT);

pinMode(10,OUTPUT);

pinMode(9,OUTPUT);

pinMode(4,INPUT);

//Serial.begin(9600);

}

void loop() {

digitalWrite(13,LOW);

if(count<2 && digitalRead(4)==LOW) /*Setting conditions for loop */

{

if(digitalRead(sensorpin)==HIGH)

{

digitalWrite(13,HIGH);

Sw.start();

/*Starting stopwatch */

delay(100);

count=count+1;

if(count==2)

{

Sw.stop(); /* Stopping stopwatch */

Elapsed=Sw.elapsed();

rpm=60000/Elapsed;

//Serial.println(rpm);

Display(rpm);

Sw.reset();

count=0;

}

}

}

}

Here we have used Arduino ‘millis()’

function for time keeping.

·

Constrain on the motor: -

Suppose the sensor is placed at distance r’

from the rotor centre. The width of the square cut is ‘h’.

Let the RPM of that particular machine is ‘R’.

The angle at the centre = ɵ =h/r'

t=60/2πR*θ second(s)

S0,θ=2πRt/60 rad

=>h/r'=2πRt/60 rad

=>h=2πRt/60*r' rad

Assuming the width is very small, time

required to travel that angle is ‘t’.

For example, let R=300, r’= 3cm.

Arduino takes very less time to sense the rotation, let us take it as 1

millisecond.

Then the maximum width

Which is equals to 0.09 cm. So if the

width is greater than this the result obtained by that circuit will be

ambiguous. We intentionally introduced some delay in the code as to cut a width

of 0.09cm is very difficult.

·

Constrain on Atmega8A-PU microcontroller: -

ð Let, the time required to sense two consecutive movement detection

is ‘T’. That is uC can’t do no faster than this.

Then the maximum rpm it can measure

For example if T= 1 millisecond then

RPM = 1000.

·

Conclusion: -

The

total cost of that project is INR 500. The results obtained by our measurement

circuit are highly satisfactory. We also plotted the voltage across motor and

corresponding RPM.